Two case studies of projects undertaken by Avant Technik

Original Design Concept

Fall Buddy

Trailermate

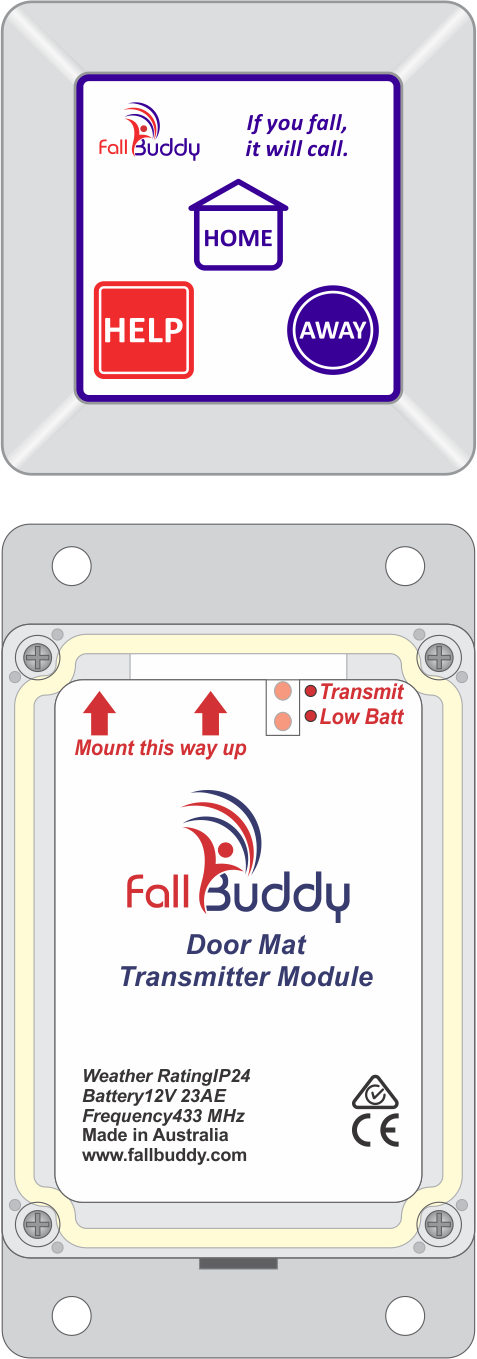

The original Fall Buddy design concept was a unit that could detect if an elderly resident has had a fall, or been inactive for other reasons, for a preset period of time. The concept would function even without the use of a panic pendant or other wearable device, and be totally unobtrusive to the user.

Our client decided that there should be an easy way for one person to check the lights of a trailer. Being a qualified electrician, he drew up a circuit of the concept, which formed part of the design brief. We then took that concept and designed a custom solution that met and exceeded those requirements.

User Interface

Fall Buddy

Trailermate

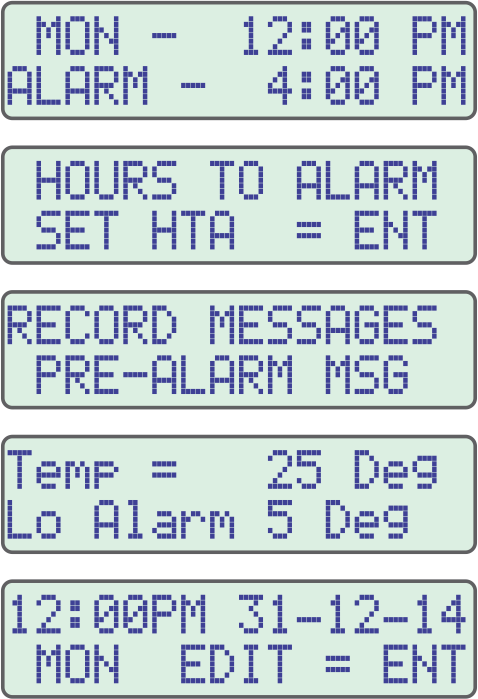

Large character for elderly users.

Hide display and setup keys for general use to prevent confusion and simplify operation.

Display to have a backlight, but dim enough to not be annoying at night.

Spill-resistant keypad with large buttons.

Main keypad buttons to also be backlit.

Hide display and setup keys for general use to prevent confusion and simplify operation.

Display to have a backlight, but dim enough to not be annoying at night.

Spill-resistant keypad with large buttons.

Main keypad buttons to also be backlit.

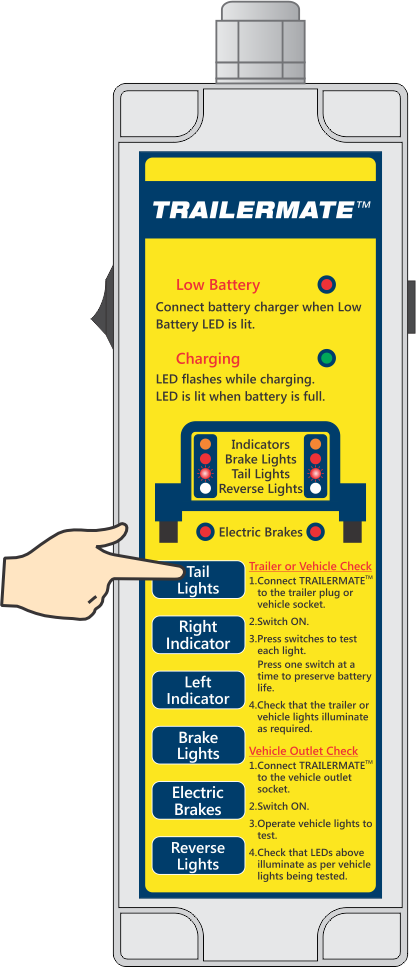

Our client originally specified a rotary switch which simply points to the light to be tested, a push-button on/off switch and LEDs that protrude through the enclosure face.

Avant Technik identified this configuration as potentially easily damaged and not waterproof. We provided a concept of an alternative solution employing a waterproof membrane keypad, with individual buttons and LEDs for each trailer light to be tested.

Enclosure

Fall Buddy

Trailermate

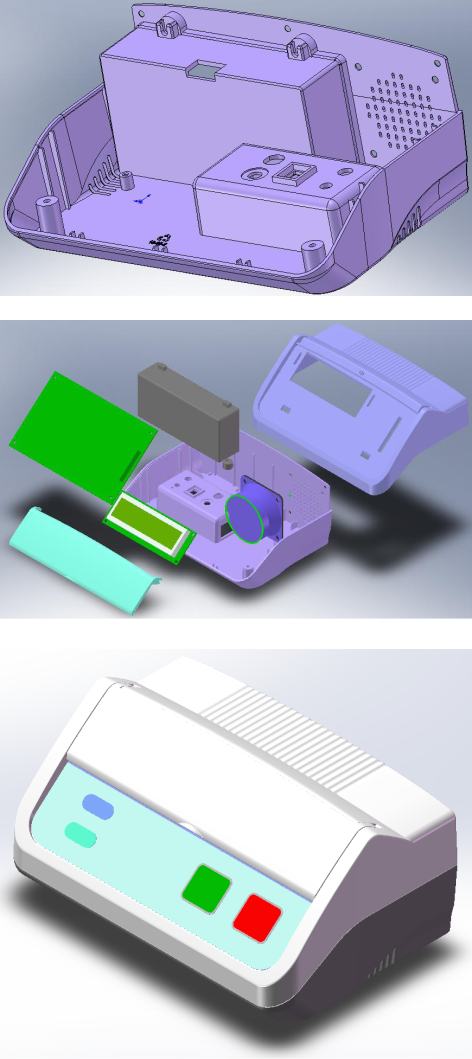

Our client’s requirement was for a bespoke, custom designed enclosure that could house the electronics and a rechargeable battery. A swing-flap to hide the LCD and setup buttons was asked for, to give the unit a cleaner, simpler appearance.

Avant Technik liaised with our industrial designer and several options were provided. Once the client settled on the final design, an initial enclosure was rapid-prototype machined for evaluation. When this was approved, Avant Technik arranged for the injection moulding tooling to be made.

Avant Technik liaised with our industrial designer and several options were provided. Once the client settled on the final design, an initial enclosure was rapid-prototype machined for evaluation. When this was approved, Avant Technik arranged for the injection moulding tooling to be made.

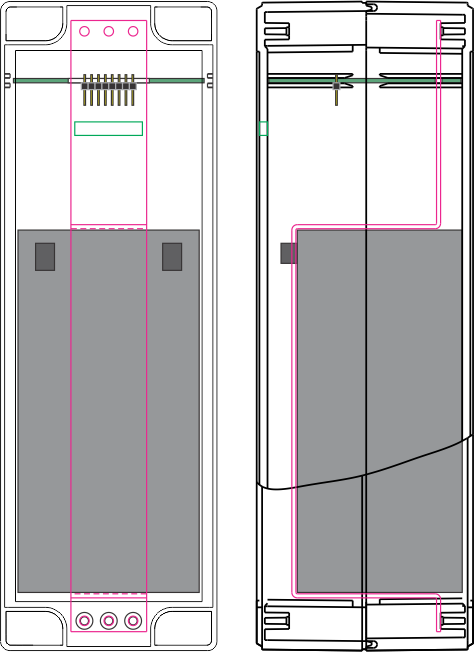

One of this client’s needs was to get their product to market quickly and to keep initial investment to a minimum. An off-the-shelf enclosure was selected which could house the circuit board and high capacity lead acid rechargeable battery.

Circuit Board

Fall Buddy

Trailermate

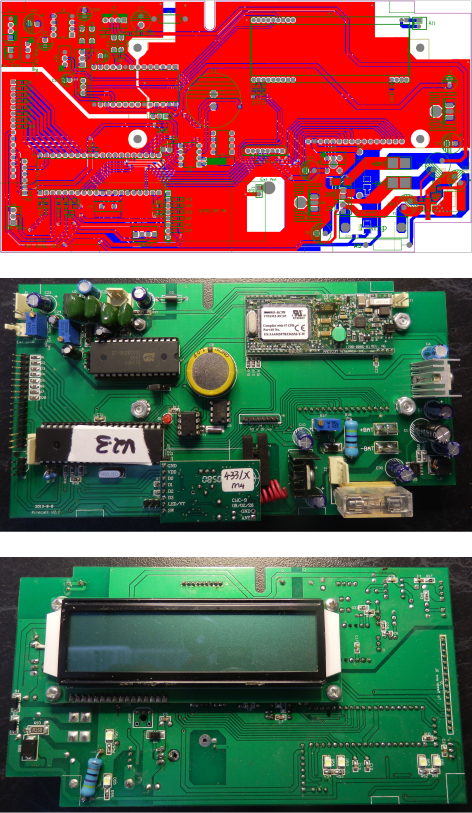

Avant Technik documented all design requirements, then designed the

circuit board accordingly.

Some specialty components required include an on-board modem, analogue voice recording module, audio amplifier and support for a USB port adaptor.

Prototypes were initially produced and tested, and subsequent final production design was then finalised.

Some specialty components required include an on-board modem, analogue voice recording module, audio amplifier and support for a USB port adaptor.

Prototypes were initially produced and tested, and subsequent final production design was then finalised.

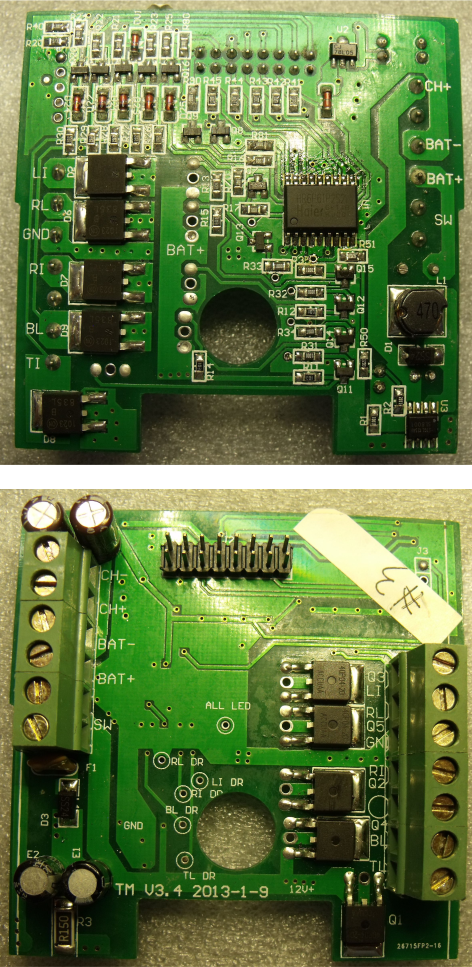

A unique type of two-way circuit was required for Trailermate’s circuit board. One way of using the final product is to illuminate trailer lights as each button is pressed. The other testing method is to connect Trailermate to the vehicle, and check that the LEDs on Trailermate illuminate when the vehicle’s lights are operated.

Prototypes were designed and tested, before completing the design for production.

Prototypes were designed and tested, before completing the design for production.

Firmware

Fall Buddy

Trailermate

As with any other microprocessor based device, the firmware code is the heart of the Fall Buddy system. This was by the far the largest area of development. An initial Beta release was produced, then several sample units installed in real world situations. The resulting feedback from actual users, rather than design engineers, helped us to improve the firmware and even add some new features.

On a relatively simple device such as the Trailermate, the firmware complexity is not as high as other products. However, having a low cost micro saves a number of components that would otherwise have been needed which helps to keep production cost down. It also means that some aspects of the design are flexible, and can be changed with a simple edit, rather than a circuit design change.

Prototypes

Fall Buddy

Trailermate

An initial prototype circuit board was built when the circuit design was completed. A large scale prototype unit was produced, purely as a hardware testing platform. This enabled firmware development to commence immediately, while enclosure design and other long term tasks were undertaken.

Since the overall Trailermate design concept was straightforward technology, we chose to make a set of prototypes that were pre-production examples. This enabled the client to show samples to prospective customers, to ensure that the final design met with market approval.

Instruction Book

Fall Buddy

Trailermate

For this project, Avant Technik wrote the instruction book. All photography, drawings and text was authored by Avant Technik. Fall Buddy is a low volume niche product, so Avant Technik also printed and bound the instruction books in-house.

Click to download Fall Buddy Handbook.

Click to download Fall Buddy Handbook.

Another project for which Avant Technik undertook the writing of the instruction manual. Some client-supplied photography was used on the front cover, but all other photos, drawings and text were authored by Avant Technik.

Click to download Trailermate Handbook.

Click to download Trailermate Handbook.

Packaging

Fall Buddy

Trailermate

For Fall Buddy, we were asked to produce high quality packaging which reflected the value of the products. The packaging also had to be able to withstand air courier shipments in satchels.

We created a high quality, closed cell foam interior, laser cut to exact size, to hold the Fall Buddy and all accessories and options. The packaging itself is white cardboard with a folding design that requires no packing tape. Sliding over that is a glossy, full colour printed sleeve.

We created a high quality, closed cell foam interior, laser cut to exact size, to hold the Fall Buddy and all accessories and options. The packaging itself is white cardboard with a folding design that requires no packing tape. Sliding over that is a glossy, full colour printed sleeve.

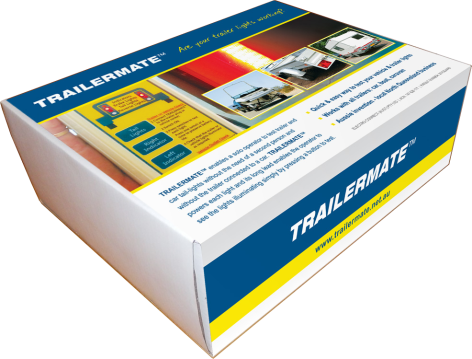

The Trailermate is packed in a white folding carton made in a custom size to suit the unit, 10m cable, optional adaptor connectors, charger and instruction book.

Final appearance is of a quality, professional product using a full colour printed cardboard sleeve.

Final appearance is of a quality, professional product using a full colour printed cardboard sleeve.

Future Development

Fall Buddy

Trailermate

After the initial release of Fall Buddy, we assisted with the addition of extra functionality such as reminders to take medicine, remote buttons for fitting throughout the home, a bed sensor input, and a special mode for dementia patients with front door exit sensor.

Future improvements will be full voice and data via the cellular network, real-time internet access for remote assistance, and battery-free wireless detectors.

Future improvements will be full voice and data via the cellular network, real-time internet access for remote assistance, and battery-free wireless detectors.

We have designed a bespoke keypad for a special version Trailermate for Australian Defence Force vehicles.

A 24V version for trucks will also be developed.

A 24V version for trucks will also be developed.

Other OEM brands manufactured or partly manufactured by Avant Technik

Bionizer is Australia’s premier supplier of chlorine and salt free pool systems for over 18 years. Since 2008, Avant Technik has been responsible for design, production, logistics and back-up service for this advanced, innovative range of pool products.

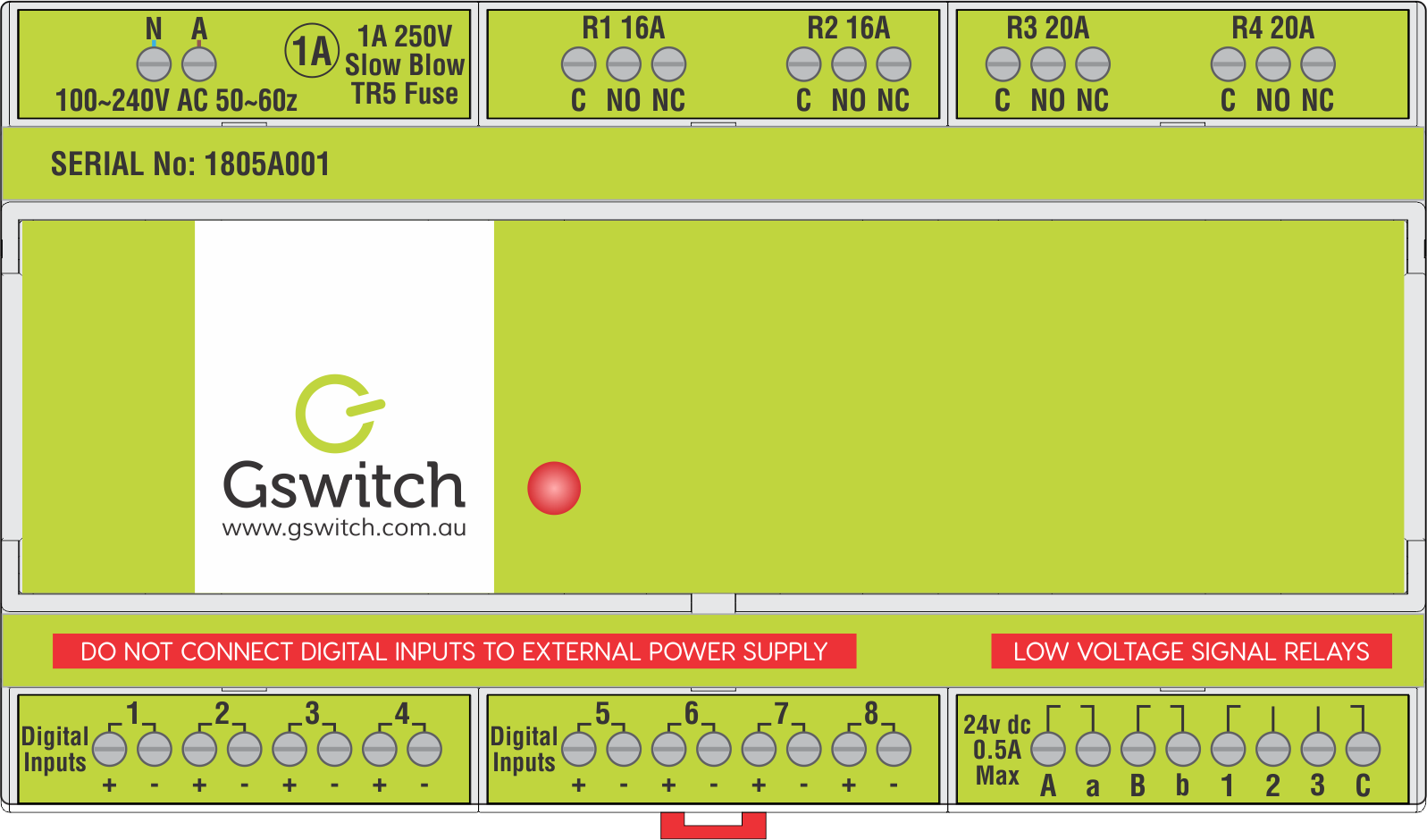

Gswitch is a product of Intelligent Automation. It is an energy management system like no other. With a quad core processor, internet connectivity and compliance with the latest demand response tariffs, it is streets ahead of any other products in this category. Avant Technik has been responsible for the hardware design for this product. We will also be producing Gswitch right here in Australia.

GSwitch is an example of a product where our client had a great deal of their own expertise, plus that of a dedicated software developer. Avant Technik was able to work within this collaborative framework to develop the final product.

GSwitch is an example of a product where our client had a great deal of their own expertise, plus that of a dedicated software developer. Avant Technik was able to work within this collaborative framework to develop the final product.

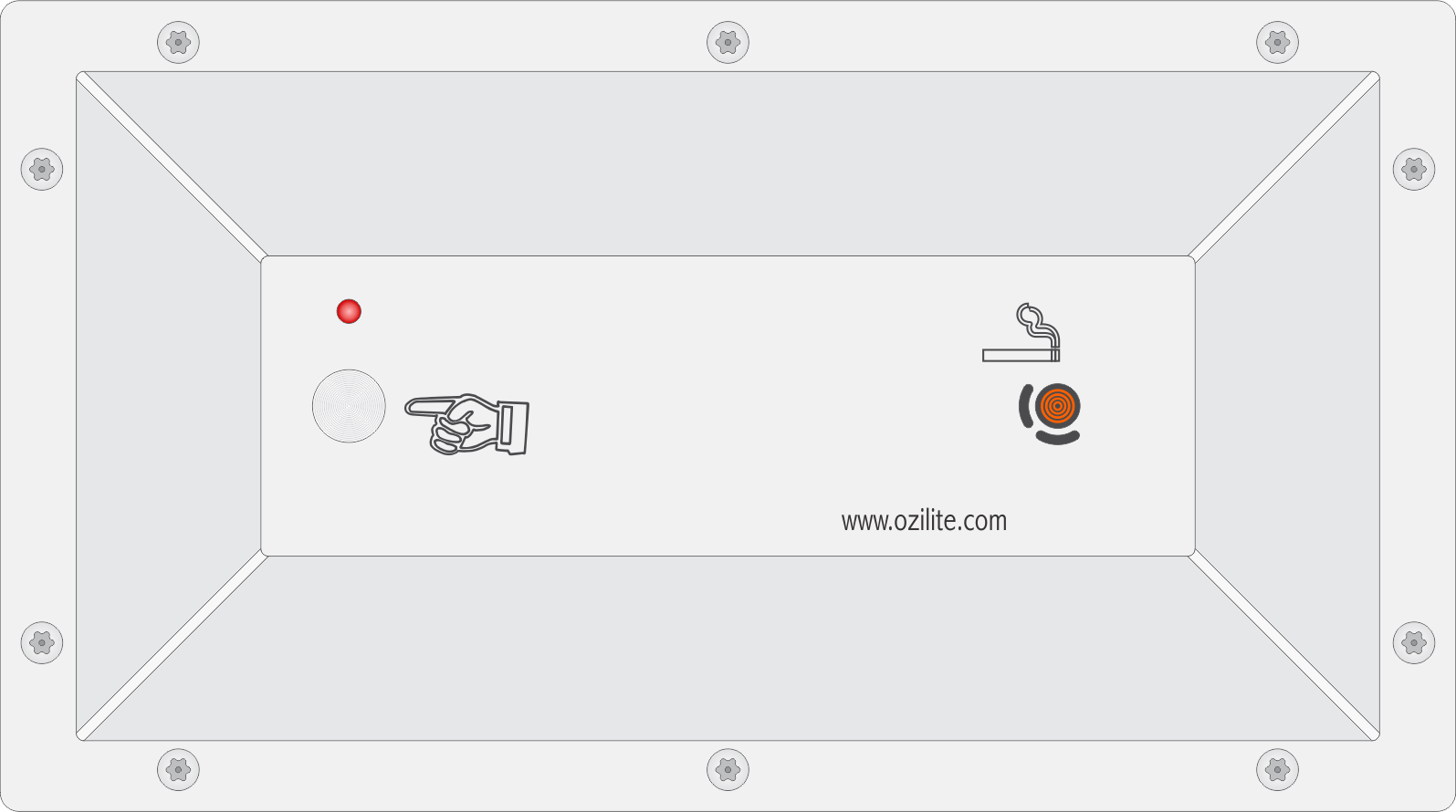

Ozilite has been producing their range of flame-free cigarette lights for many years. The initial relationship between Ozilite and Avant Technik has been the supply of some components such as transformers and printed circuit board assemblies. This will grow in the coming months to Avant Technik sourcing the high quality precision metalwork, and finally to Avant Technik producing the entire product range for Ozilite.

Auto Ingress is a producer of automatic door opening systems for commercial properties. Avant Technik designed and supplies them the enclosure and keypad for door controller.

Avant Technik is happy to work with our OEM customers in whatever capacity is required. In this example, we are the supplier of two components, as Auto Ingress is capable of dealing with much of their own production work.

Avant Technik is happy to work with our OEM customers in whatever capacity is required. In this example, we are the supplier of two components, as Auto Ingress is capable of dealing with much of their own production work.